Machining

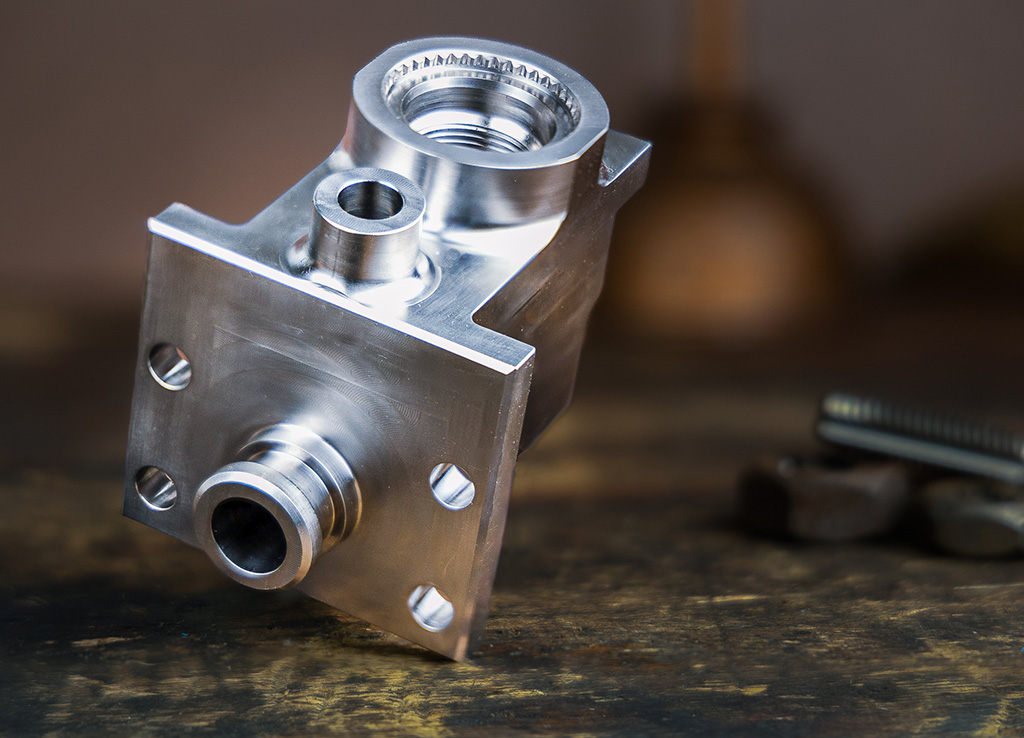

Milling

Our machining centers are equipped with the most advanced milling technology, enabling us to produce the highest precision parts on-time and on-budget. We offer clients:

- 3-, 4- and 5-axis milling capabilities for an infinite number of possible part shapes.

- Machines that are durable and dependable for long-term accuracy and consistency

- On-board probing for part location and feature inspection

- Powerful CNC controls that simplify programming and increase productivity

- Pallet changers that increase spindle utilization and reduce part cycle times

Since we have invested in world-class machines, we can handle everything from prototypes and short runs to high production and everything in between. We work with a vast array of materials and have experience working across many different industries, including aerospace, automotive, industrial, and medical.

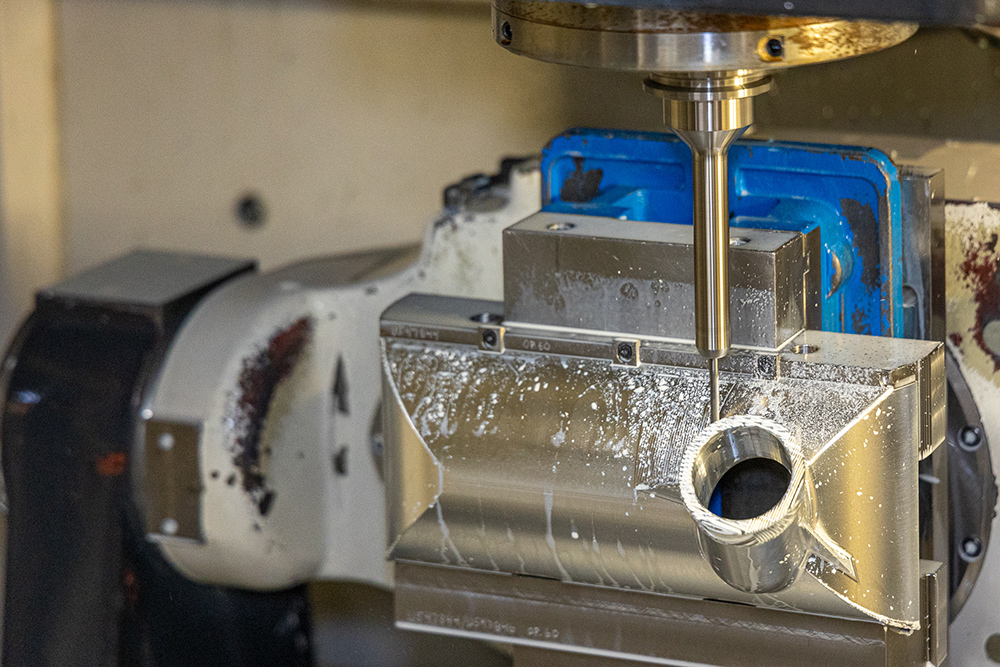

5-Axis

5-axis machine technology gives us the ability to develop complex workpieces without resetting or moving parts to a different machine. With the ability to produce highly complex components in a single setup, our 5-axis machines enable us to:

- Increase productivity and improve delivery times for complex parts

- Save time and money with less fixture preparation

- Achieve higher part accuracy

- Achieve superior surface finishes and overall better part quality

5-axis is an innovative machining method that provides infinite possibilities as to the part sizes and shapes we can effectively produce. That’s why we are proud to offer 5-axis machining to clients of all sizes, in all industries.

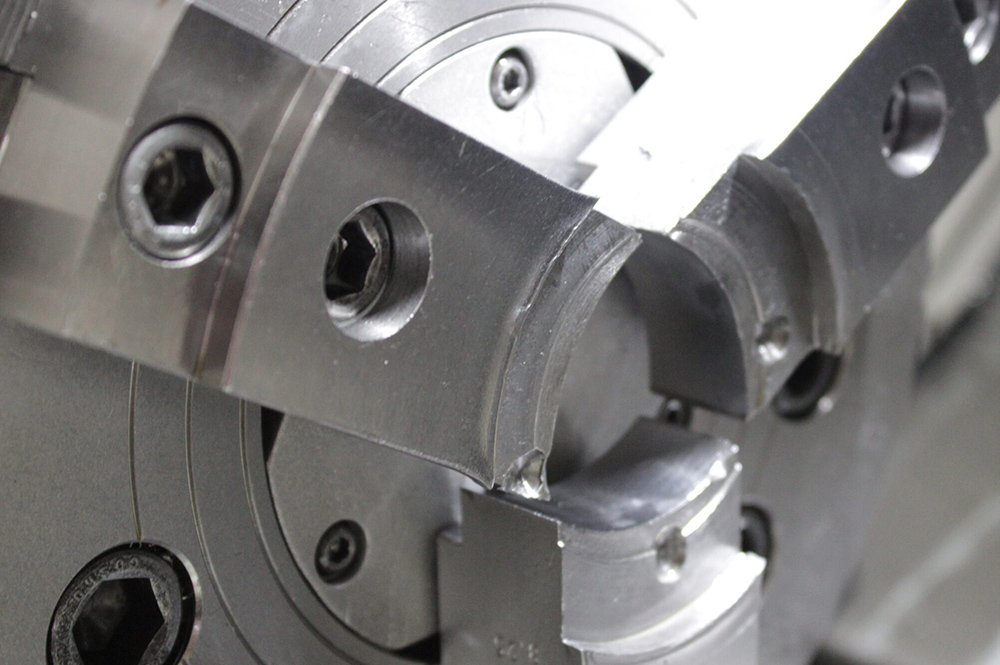

Turning

We operate CNC turning centers ranging in size and capacity, from two-axis models to machines with rotary tool spindles and second spindles. Our turning centers incorporate the latest, most advanced turning technology for boosting productivity, including:

- Second spindles offering back-side finishing or sequential part processing

- Rotary tool spindles deliver the milling, drilling, and tapping performance of a machining center

- Y-axis functionality with greater range of part geometry machining

- Bar feeding capability increasing production and enabling lights-out operation

If you need high-precision parts, Winndeavor has your solution. With CNC lathes that deliver fast, accurate, and aggressive metal removal capabilities we are your single source provider of turned parts.

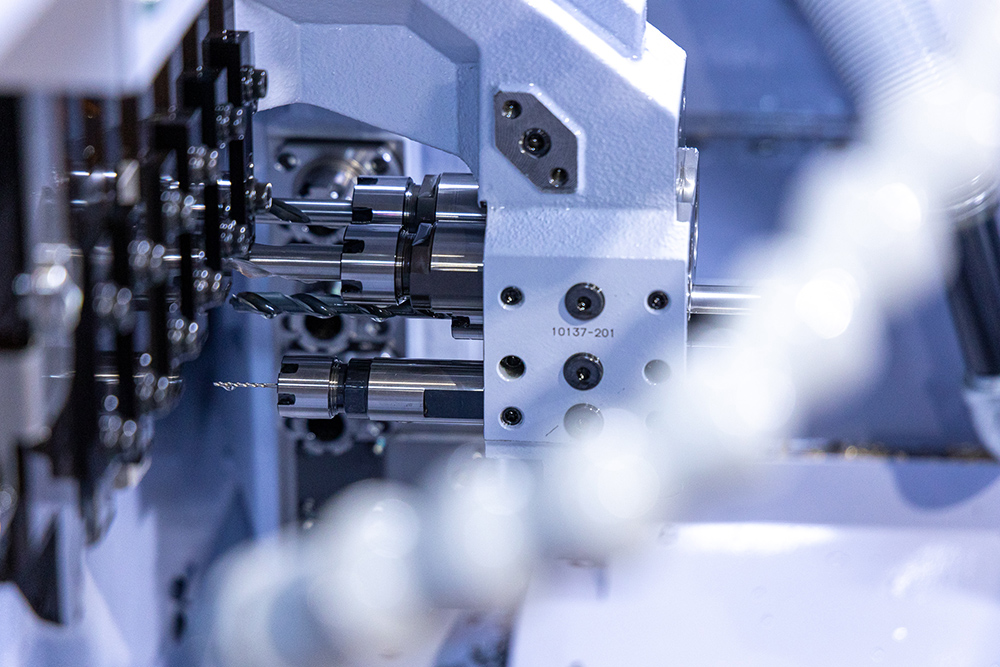

Swiss CNC

When our customers need small, complex precision parts, particularly in the medical, aviation, and metalworking industries, we rely on Swiss-type Lathes to get the job done. Swiss CNC is a specialized modern precision machine that can process extremely small parts quickly and accurately. Our Swiss machines feature:

- Excellent accuracy and efficiency

- High rapid feed rate and a power-driven sub-spindle tool to greatly reduce processing time

- Flexible, complex machining in a single setup

- Maximum tooling variations to meet manufacturing needs across multiple industries

Winndeavor is built on quality results. With the use of the most advanced CNC Swiss lathes, we can produce high-quality precision parts of all sizes. No matter how complex the desired workpiece is, we can offer you a suitable, cost-effective solution.

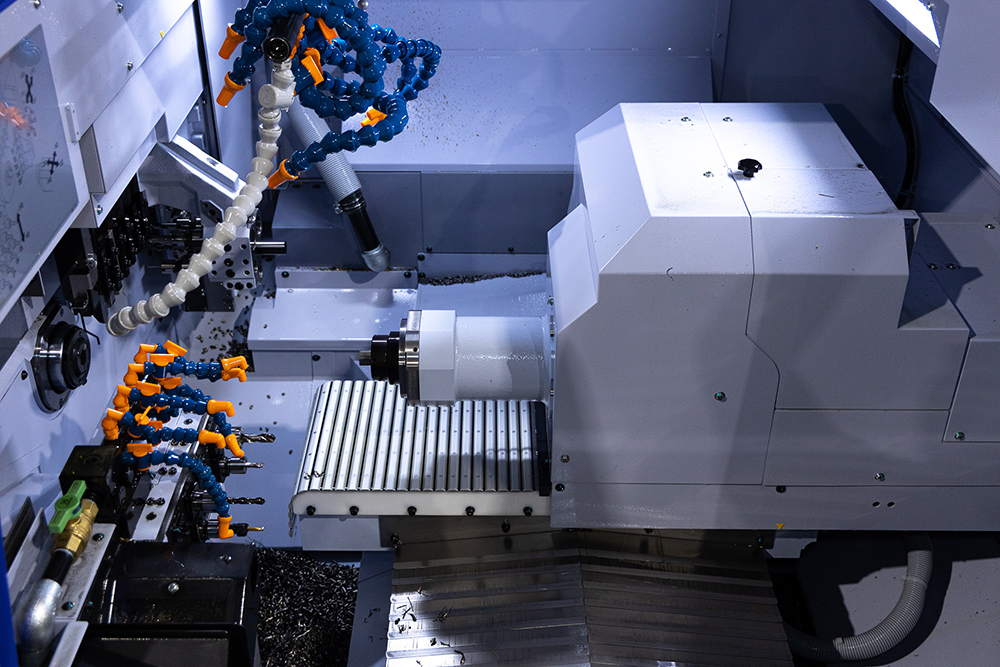

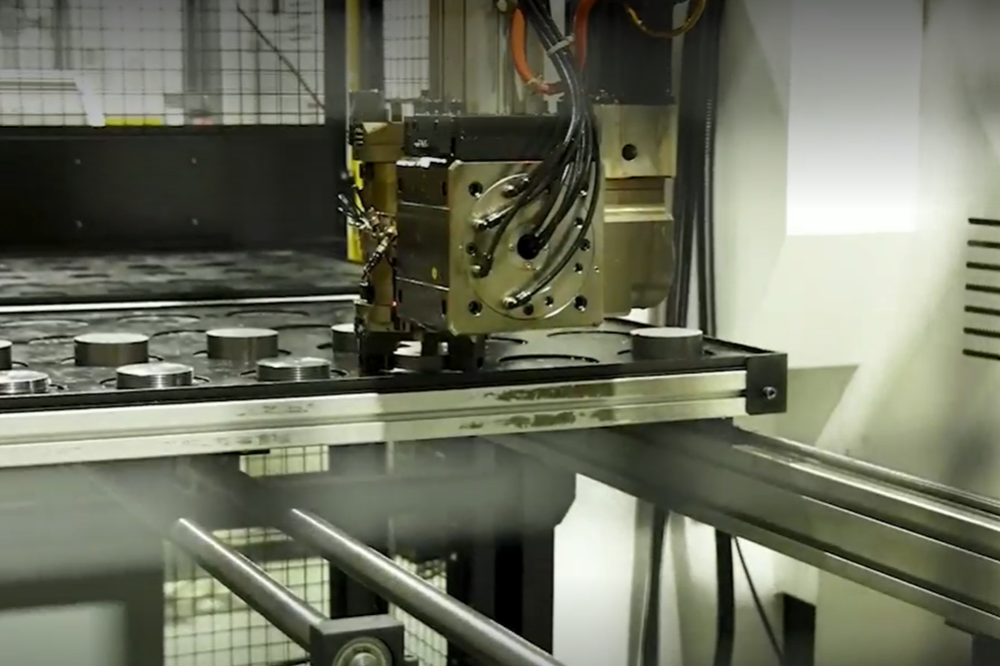

Automation

Automation can enhance productivity through increased machine tool utilization. Winndeavor integrated automated systems into our key operations, and we pass the competitive advantages to you. Examples include:

- Bar feeders

- Gantry Loaders

- Palletech Automation Systems

- Articulating Robots

The result for our clients? Faster delivery, lower costs, and increased capacity. That’s why we provide customers with a full range of automated machine tools capable of helping them meet their specific production needs.

Industries we serve

There is no shortage of industries that rely on the highest-quality machined parts. As an AS9100D and ISO 9001:2015 Certified shop, Winndeavor takes pride in serving companies in those sectors.

Commercial Aerospace

Defense Aerospace

Orthopedics

Manufacturing

Railroad

Client Testimonials

Client Testimonials

Boss Industries and Winndeavor's relationship goes back almost 30 years. From the infancy of Boss and a limited line of products to our current status of manufacturing several very diverse and specialized lines of products throughout the world, our relation with Winndeavor has been a positive one.

Regardless of machining needs for 5 or 3000 parts, Winn has fulfilled our requirements and has worked with Boss as our company has grown. Winn has assisted our engineers with design and processing recommendations. Winn’s suggestions and guidance provided a win/win situation for both companies with precision machining components, and other support items, too many to list. Nevertheless, we would just ask and if Winn Machine could help, they would.

I would strongly recommend Winndeavor as a trusted supplier.

— Paul

I’ve worked with Winndeavor for many years, and have always been impressed with their level of customer service—from their help with product inception and drawing clarification to quoting, to final delivery.

— Judy

A strategic partner of ours for decades, this relationship has been based on trust, respect and firm business practices. They have continued to improve processes and machinery as time has evolved. This has allowed us to stay competitive in our market as we can supply machines containing machined components of the highest quality.

I could not have asked for a better long term partner to work and grow with.

— Jay

Contact Us

Winndeavor

1712 Genesis Drive

LaPorte, IN 46350

219-324-2978

Let's Talk

When you need a reliable, top-quality machining and fabrication partner, Winndeavor is here for you! Fill out the form below to contact us today.