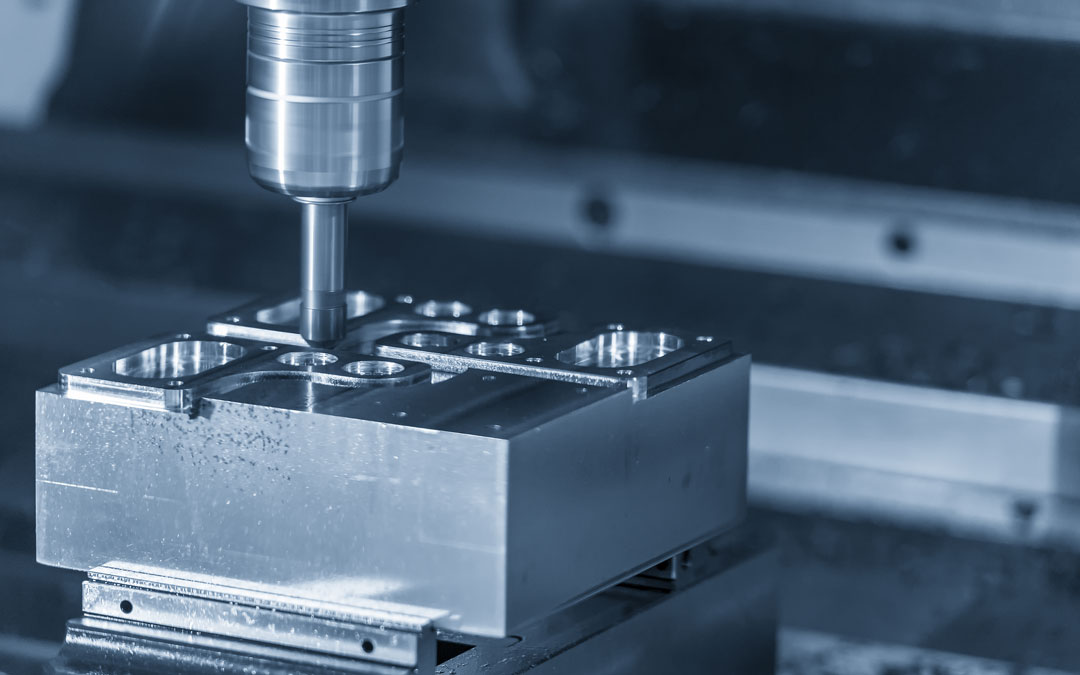

Milling is one of the most common machining processes found in the metalworking and manufacturing industry. It may be surprising to know that milling itself is not just one procedure, rather, there are numerous types of milling operations, each with different intricacies which make them more suitable for the needs of the finished part. Let’s take a look at some of these operations.

Learn the Ins and Outs of 5-Axis Machining

Slot Milling

In this process, the width of the cutter is less than the width of the workpiece: it is used to make a slot in the workpiece. Thin cutters make for thin slots. To cut the piece in two, a very thin slot can be made to go through the depth of the workpiece. Another name for this process would be “saw milling.”

Vertical Milling

Vertical milling machines have the spindle in vertical position or parallel to the column phase, mounted onto a sliding head for more complexity. The most common tool used in vertical milling is the end mill or a flat-bottomed cutter. In some cases, it may refer to round-nosed cutters as well.

Horizontal Milling

A horizontal milling machine is best for forming flat surfaces, dovetails, keyways, and gears. These machines are best operated through and up milling process whereby the metal is fed into the cutter against its rotating direction. Compared to vertical milling, horizontal milling can exert maximum force against the jaw holding the workpiece.

Side Milling

When the goal is to produce a flat vertical surface in the workpiece, side milling is the operation to choose. The depth of the cut can be manipulated by rotating the vertical feed screw of the table.

Gang Milling

When two or more milling cutters are used together on one arbor while cutting horizontal surfaces, this is known as gang milling. The usual method is to mount the milling cutters of different diameters, shapes, and/or widths on an arbor. The potential combinations of cutters are unlimited and are determined in each case by the needs of the job.

Straddle Milling

When you need two or more parallel vertical surfaces machined in a single cut, straddle milling is what you need. The process is accomplished by mounting two side milling cutters on the same arbor, set apart such that they straddle the workpiece.

“Milling” constitutes a whole genre of machining operations.

Up (and Down) Milling

Also referred to as conventional milling, up milling is when the cutter rotates against the direction of the table feed. Contrast this with down milling, where the cutter rotates along the direction of the table feed. The difference? In up milling, the chip load on teeth increases gradually while in down milling, the chip load on the teeth decreases.

Form Milling

The form milling process allows for machining special contours composed of curves and straight lines—or potentially only curves—in a single cut. This is done with formed cutters, those shaped to the contour of the cut, or with a fly cutter ground specifically for the job. More common form milling involves milling half-round recesses on the workpiece.

Face Milling

In face milling, the size and nature of the workpiece determines the type and size of the cutter required. The teeth on the periphery of the cutter does most of the work, however, if the cutter is properly ground, the face teeth remove a small quantity of stock which is left as a result of the springing of the workpiece or cutter, producing a better finish.

Turret Milling

Turret milling is done by drilling, cutting, and shearing. The spindle is stationary during the milling process, while the table moves along the X and Y axes. This process is often used for “lighter” operations.

As you can see, the world of milling is diverse, containing many different techniques, tools and outcomes. The next time you think about milling a part, keep in mind the vast array approaches a seasoned machinist has at his disposal to get the job done.