In the past, manufacturing was slowed by drawing designs by hand. Today, industries have advanced thanks to computer-aided design software. With new ways to model and adapt blueprints, CAD support has enabled engineers to streamline their production processes. Despite its growing adaptation into businesses, though, some companies know little about how computer-aided design works, let alone how it can help production. Together, let’s go over the basics and advantages of computer-aided design (CAD) businesses can expect.

Check out our Guide to CNC Lathes

What is Computer-Aided Design?

Computer-aided design (CAD) is computer software meant to help in creating, modifying, analyzing, and overall improving a design. Through CAD software, product designers can enhance productivity, quality, and documented communications throughout their business through a specialized database.

Various industries rely on computer-aided design to draft models through its 2D and 3D design applications. Yet, CAD software purposes go beyond just shapes, as its complex design capabilities in technical and engineering drafts can exchange information on product components, too. Essentially, computer-aided design can lay out the specific materials, production process, dimensions, and even limits of a particular product.

How do Manufacturers Use Computer-Aided Design?

CAD software is popular amongst many important industries mostly for its analysis function; simply, CAD software tells how different materials may interact each other throughout production, enabling designers to adapt the model until completion. Some industries that benefit from this process include architecture and construction, advertising, and multi-media. Let’s take a closer look at CAD’s presence in machine shops in producing better parts.

- Engineering: Engineers from automotive to aerospace often rely on computer-aided design programs when drawing up new production models in their fields. Accounting for safety measures in design, CAD software proves itself within engineering to measure the quality of the final product, which is especially important for manufacturers of circuits, communication networks, and medical machines.

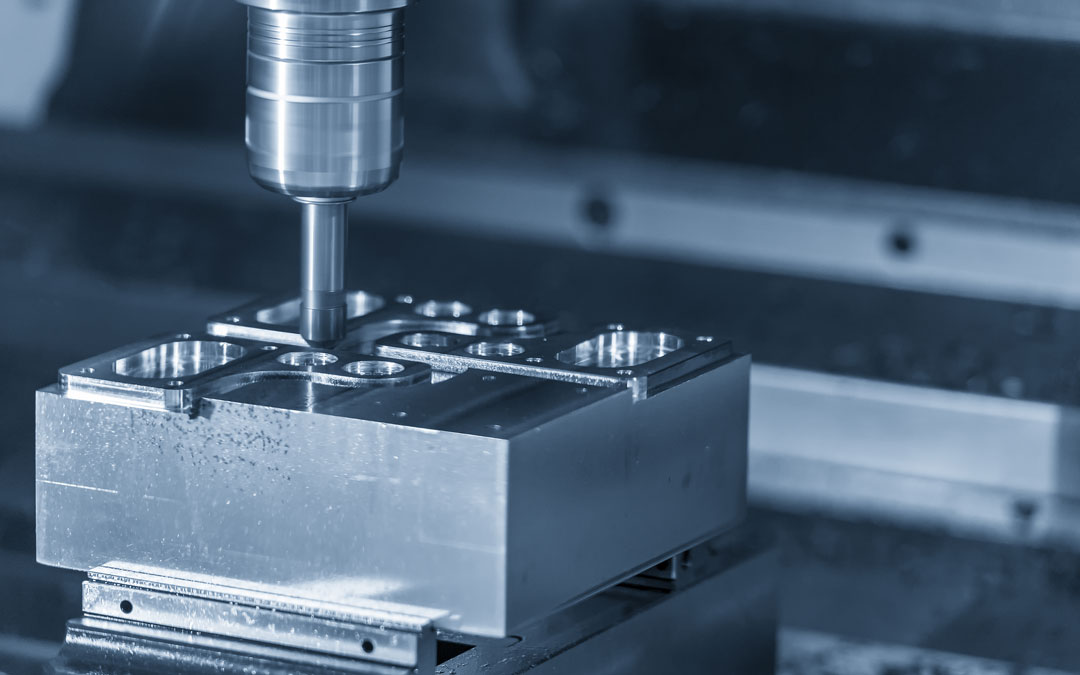

- Manufacturing: Many manufacturers across industries use CAD programs throughout both the designing and manufacturing process. Using 3D modeling, the software helps manufacturers magnify fine details or rotate the part image in order to better conceptualize and alter the measurements before final production. In a sense, computer-aided design allows manufacturers to examine the elements of a system or part inside and out, even going so far as to simulate how well it functions in terms of speed, placement, or limitations. As a result, computer-aided design helps improve manufacturing processes to both improve the quality of each piece created, but also allow designers to alter and reconfigure their designs for optimal functionality before mass-production.

Computer-aided design helps teams collaborate on projects and edit designs seamlessly throughout the production process.

Advantages of Computer-Aided Design

Overall, CAD software helps various professional industries design products, draw blueprints, and digitally alter graphics to produce unique items within the market. However, businesses may wonder what specific advantages computer-aided design brings to their production process. Below, we lay out the advantages CAD has to offer:

Increased Productivity

The main advantage of CAD software is how it saves significant time during the production process. Since the program allows designers to alter and adjust digital files at any time, production becomes streamlined, cutting wasted time as well as costs in the long-term.

Less Error

By automating tedious design functions, computer-aided design helps to limit the risk of error within the production process. Without requiring input after drawing, CAD software can prevent mistakes from human error, product redesign, manual testing, or personal design changes which could waste time and energy. In addition, CAD makes communication of product design quite clear, reducing error and potential upset between teammates by allowing everyone to see changes to the final piece.

Simplified Information Sharing

As computer-aided design programs enable organizations to access product changes and file history, these files can be exchanged or reviewed by clients, vendors, or department teams to check production quality. With cloud-based CAD systems becoming mainstream, businesses can easily collaborate on projects in-person or remotely, thereby improving information sharing processes in B2B, assembly interactions, marketing communications, and even customer experience based on high-levels of product design or presentation.

No matter which industry your organization works in, implementing CAD software into your manufacturing process guarantees these advantages of computer-aided design and so much more. As leaders within the manufacturing industry, Winn Machine recognizes the enhancements computer-aided design software offers to daily manufacturing and production processes. To learn more about integrating CAD software or other lean processes into your company, contact us at Winn Machine today!