Click Here to Learn About Setting Up Vendor-Managed Inventory

HOW THEY WORK

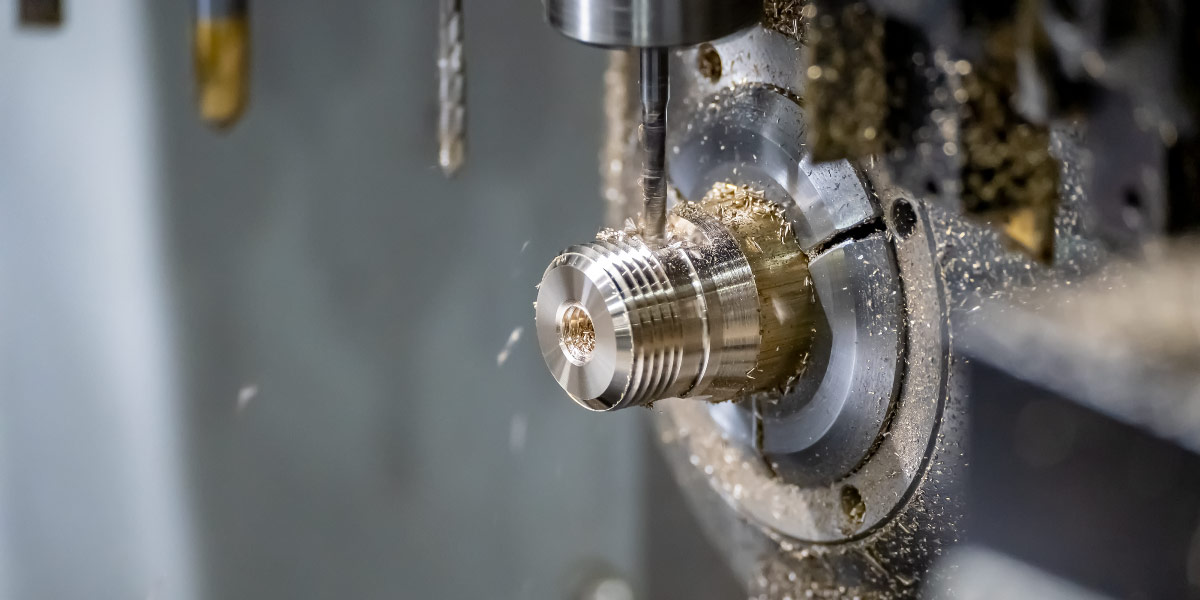

The secret of the Swiss machine’s success is in its design. With Swiss machines, the barstock spins and slides through a guide bushing. This provides a powerful point of support, regardless of workpiece length. Turning tools are mounted to the face of the guide bushing and cut the stock near the bushing. Gang slides carry holders for various types of tooling, and can also support live tooling. Many Swiss machines feature a sub-spindle and back-working tool stations, dramatically increasing the functionality and throughput capability of the machine.

Swiss lathes are great for small, complex parts.

THE SWISS ADVANTAGE

The primary advantages of Swiss machines come from both the guide bushing, the geometry, and mechanics in the tool zone. Parts in Swiss machines deflect and vibrate less during machining than in traditional lathes. And since these machines are relatively compact and the tools do not have to move very far, the chip-to-chip time from one tool to the next can be extremely short—one second or less!

A Swiss machine can produce complex parts using simultaneous operations and may be able to have as many as three or four tools cutting at the same time. Since a Swiss machine can mill, drill, ream, and saw, secondary operations are often eliminated. Set it up, drop your stock in a bar loader, and a Swiss machine can run for hours unattended, producing parts that come out of the machine ready to ship.

Shops with Swiss machines can produce long runs of small, complex parts faster and cheaper than on traditional lathes, with the added benefit of freeing up other equipment to produce larger parts. The next time you’re looking for a shop to run small, high-tolerance parts in large numbers, find a shop with a Swiss machine. You will be glad you did.