It’s not presumptuous to state that computer aided design (CAD) has helped evolve the manufacturing industry into what it is today. This history of computer aided design marks many milestones, some of which have enabled precision machining to develop across various industries. But where did this software first develop? How have CAD designs changed over the years? Below, let’s examine the history of computer aided design along with the value it provides to manufacturers today.

Find Out How to Implement a VMI Strategy

Timeline and History of Computer Aided Design (CAD)

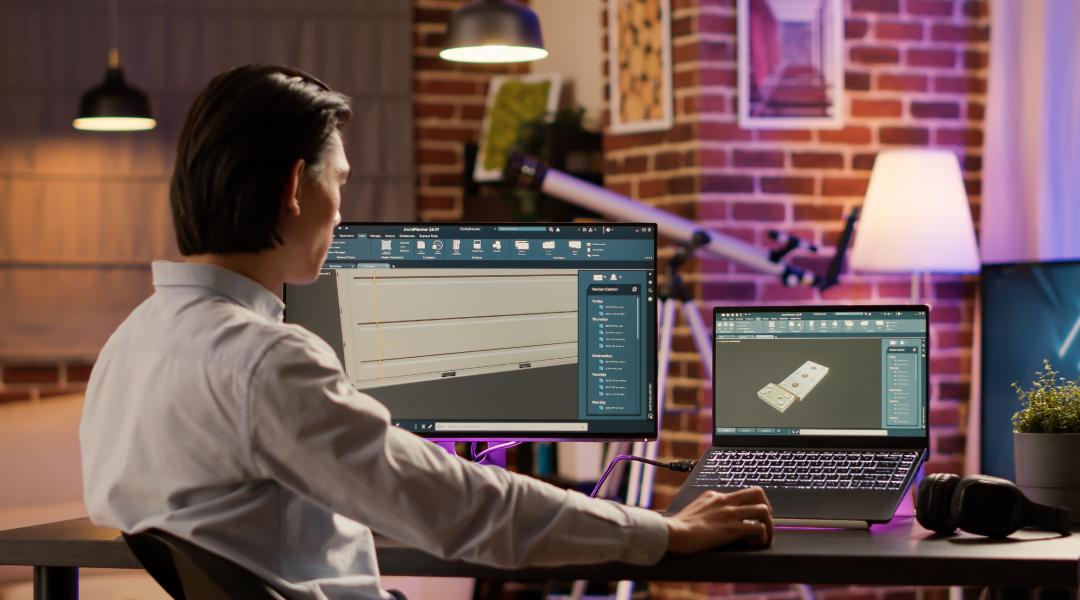

Modern manufacturers are quite familiar with computer aided design (CAD). Simply put, this software helps engineers create, modify, analyze, and improve the overall design of whatever is being manufactured. CAD software enables product designers to draft up 2D or 3D design models with advanced applications and tools, thus optimizing department communications and production quality throughout development.

But where did the history of computer aided design begin? Well, it began 60 years ago when Dr. Patrick Hanratty created the control system that would evolve in the computer aided design software we know today. This system—which he called PRONTO—was thought to be the first commercial CAD program due to its automated design processes and interactive graphics. Coupled with the fact this system displayed the same light drawing technology presented in the software today, many manufacturers acknowledge Dr. Patrick Hanratty as the ‘Father of CAD.’

As more facilities began to use computer aided design software, design productivity and processes started to improve exponentially, helping engineers save time on revisions as well as customer delivery. By the 70s, small and large businesses implemented CAD systems into production, and by the 90s its 3D capabilities would further revolutionize manufacturing and machining efforts for advanced projects.

CAD is used across multiple industries because of its ability to streamline design and manufacturing processes.

Importance of CAD in Modern Manufacturing

From past to present, the history of computer aided design has greatly impacted the processes of manufacturers today. Since its conception, CAD has assisted engineers and professionals of many fields with streamlining their precision machining, CNC cutting, and additive design efforts to the best quality.

How has CAD software made such a difference? In short: control; with the functions provided in computer aided design, precision designers can control how they interact, alter, and handle materials during production until they create the desired product. This is the exact foundation and beneficial result ensured from Computer Aided Manufacturing (CAM), which relies on CAD systems to manage the entire production process. Furthermore, designers can utilize storage within CAD software to collaborate with designers, store files, or share design specifications to automated machinery like CNC cutting machines for digital access to each model.

Numerous industries value the utility and history of computer aided design, as without it they wouldn’t have the tools to create innovative equipment. Aerospace engineers rely on CAD software tools to give detailed 3D analysis and measurements of plane engines or interior layouts. Defense specialists require CAD computing capabilities to test prototypes and accurately adjust designs to ensure the safety of defense personnel. Now, medical manufacturing is utilizing computer aided design in precision machining efforts with orthopedic, oral, and potentially exterior prosthetics.

Even now, the history of computer aided design continues to grow, expanding the capabilities of manufacturing to improve products and delivery for the future.

Join the Next Generation of Manufacturers

Time brings more ideas, changes, and creativity to form. The history of computer aided design was inspired by ways to make ideas a reality. At Winndeavor, we hope to become part of this history with our CAM efforts, using CAD software to deliver the best solutions you need with excellent designs and results guaranteed.