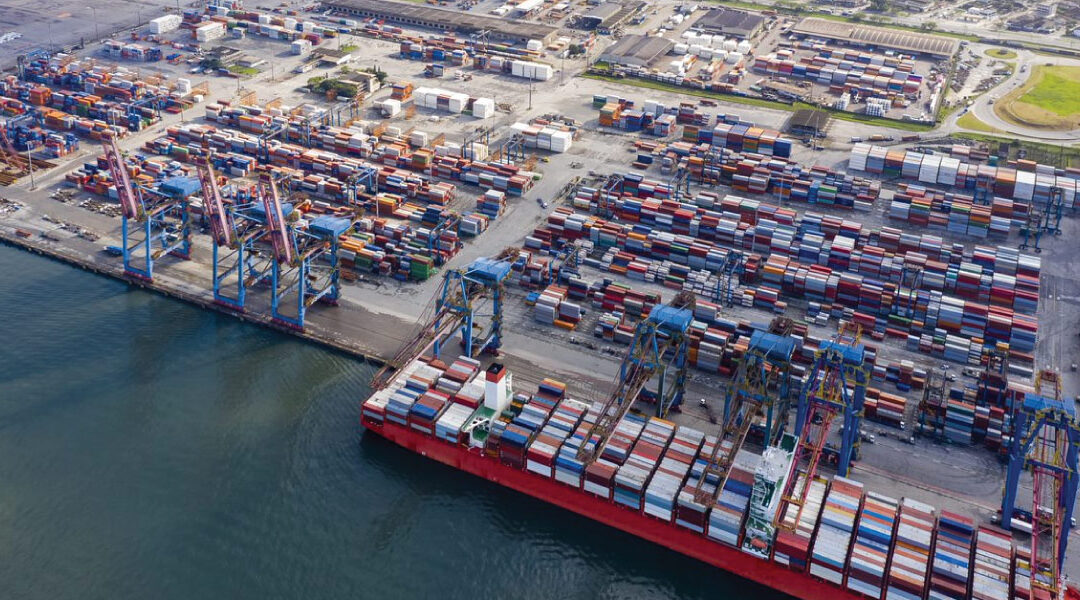

It seems that everywhere we tune into the news, there’s a story about difficulties in the supply chain. Raw materials, parts, and finished products have been getting stuck at port and facing major delays before getting to the people who need them to cut, assemble, and deliver to their customers. The lesson we all must learn is that when it comes to manufacturing, supply chain management is critical for customer satisfaction and therefore profitability. The supply chain is something that producers and consumers alike have taken for granted in the past but are unlikely to do so again for the foreseeable future.

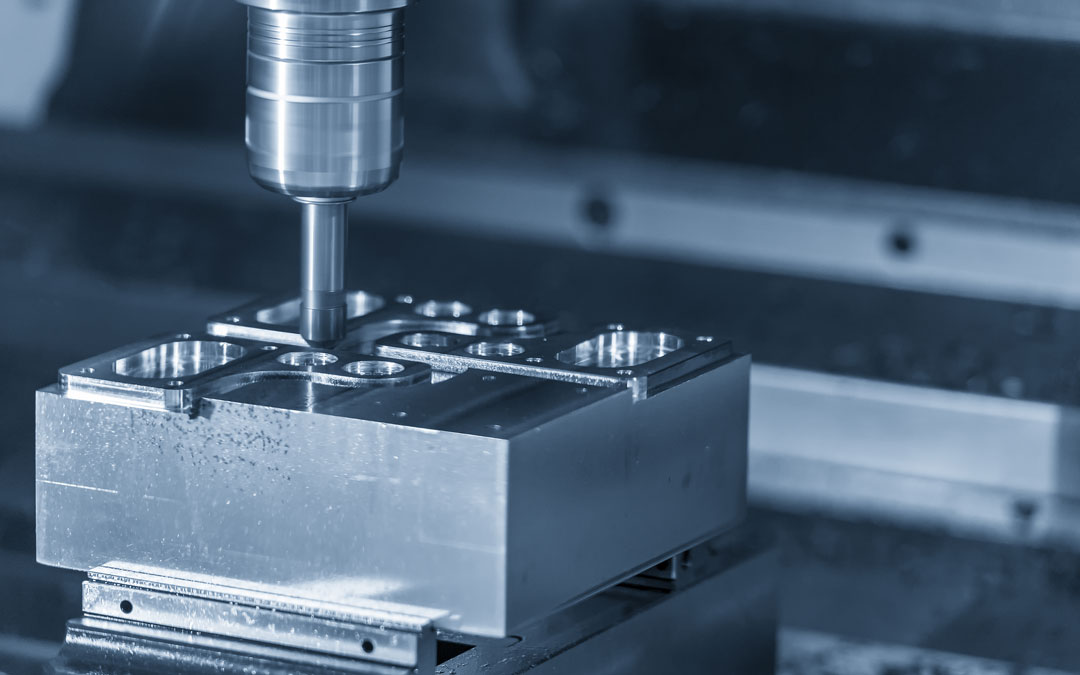

Learn the Ins and Outs of 5-Axis Machining

First, though, a question: why is it important for manufacturers to manage their supply chain? Well, an efficient supply chain is critical for any functioning business, but for manufacturers in particular, two assets are particularly important: time and money. A bottlenecked supply chain also severely limits a manufacturer’s supply of both. Which is why there are 3 key reasons supply chain management is important.

1. More complicated products

Consumers have become more demanding of the products they purchase, which has caused manufacturers to focus on how products are made—several stakeholders are involved in the production of every item.

2. Brand owners don’t build their own products

As part of the foregoing, several companies are involved in making one company’s final product. A 2018 report by CIMdata found that between 40% and 70% of consumer and industrial goods are made using procured parts and components. This allows companies to specialize in certain skills and capabilities, but when more people are involved in the development of a system, the chances of miscommunication or other errors increase.

3. Role of technology

The emergence of the Internet of Things (IoT) is changing the way manufacturers organize their operations on a fundamental level—specifically the way they organize their operations. The influx of subcontractors and suppliers involved in the manufacturing process has also slowed the flow of the manufacturing process as a whole.

Manufacturing Supply Chain Management Benefits

As noted above, the two most valuable assets for any manufacturer are time and money. Effective supply chain management promises to save manufacturers both. Supply chain management solutions allow companies to increase the speed at which they produce their items. Supply chain management also reduces distribution, production, purchasing, and overall supply chain costs. When parts are delivered quicker, clients are happier!

How Can Manufacturers Streamline Their Supply Chain?

There are many varied strategies a manufacturer may take to improve their supply chain management and reduce lead times, but the one we particularly espouse is vendor-managed inventory (VMI). In the VMI framework, the supplier is in charge of replenishing the parts when the customer needs them, which allows the supplier to be proactive when adjusting inventory to customer demand including seasonal changes, promotions, and initiatives. There are many more benefits to the VMI partnership, but chief among them is that suppliers help customers reduce both inventory overstocks and stock shortages, which means they can better navigate the difficulties that come with the bottlenecked supply chain. Winndeavor uses the vendor-managed inventory strategy to help our customers and keep our customers happy. Contact us to learn more about how we consistently meet our clients’ needs!